Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Pacific Daily journalist was involved in the writing and production of this article.

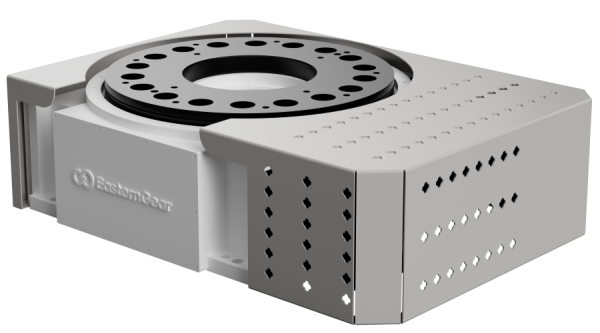

Compact High-Torque Rotary Tables for Welding Automation From EasternGear

EasternGear, a trusted name in high-precision motion systems, is making a bold statement in the field of robotic welding automation with the launch of its EGRT-series high-torque rotary index tables. Designed to deliver exceptional performance in heavy-load welding automation environments, the new models—EGRT-2500, EGRT-5000, and EGRT-7500—are capable of supporting payloads of 2.5 tons, 5 tons, and 7.5 tons respectively.

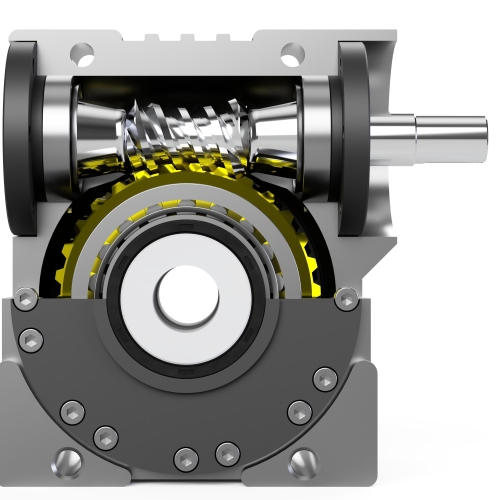

What truly sets these rotary positioning tables apart is their Barrel Cam – Double Enveloping (Globoidal) Worm Gear drive system. Unlike conventional cylindrical worm gears, the globoidal gear mechanism enables simultaneous surface contact between the worm and worm wheel. This structural advantage translates into superior torque transmission, greater durability, and a more compact form factor—making it ideal for precision welding equipment and robotic welding integration.

Despite their low-profile housing, each EGRT model is engineered to deliver outstanding force and rigidity. With maximum allowable torques ranging from 5,000 to 8,000 kg·m, and repeat positioning accuracy of ±60 arcseconds, the EGRT series ensures consistent and precise indexing even under demanding industrial loads. Each table supports ±360° rotation, making them perfect for multi-position spot welding, automated welding fixture systems, and robotic arm synchronization.

These benefits are especially critical in modern smart factories, where space-saving welding automation systems, multi-axis motion control, and high-performance rotary indexing are essential for operational efficiency. EasternGear’s globoid worm technology allows for low vertical clearance designs without compromising torque—an advantage that is crucial in automotive welding lines, industrial robotics, and heavy equipment manufacturing.

With decades of expertise in globoidal worm drive technology, EasternGear delivers more than just a rotary table—it delivers a complete welding automation solution tailored to the evolving needs of advanced manufacturing systems.

For full technical specifications or inquiries, please visit www.epglab.com

High Torque Worm Gearbox for Servo Motors – EtG Drive by EasternGear

The double enveloping worm gear has a long and distinguished history, with origins tracing back to Dr. Lorenz’s patent in 1891 (Germany) and the independent development by Samuel I. Cone in 1924 (USA).

Known for its large contact area, high torque density, and mechanical durability, this gear design remains one of the most technically advanced in the motion control industry.

However, due to its complex geometry and demanding manufacturing requirements, only a few companies worldwide have succeeded in commercializing this technology.

EasternGear, a globally competitive manufacturer based in Korea, possesses full capability to produce and customize double enveloping (globoidal) worm gear reducers.

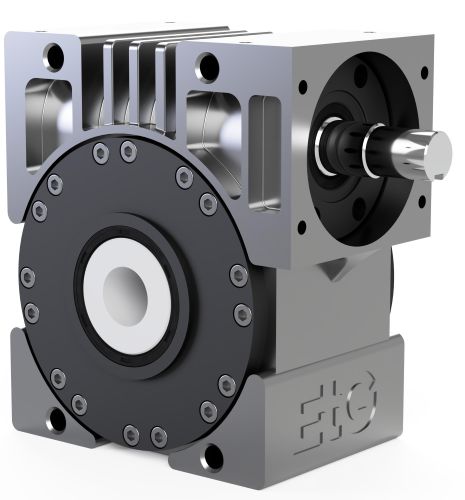

The company’s flagship series, EtG Drive, is engineered for servo motor-driven precision systems and sets a new standard in compact power transmission.

EtG Drive is available in High-Torque and Standard models, offering gear ratios from 5:1 to 50:1 and center distances from 50mm to 120mm as standard.

For specialized applications, custom configurations are available upon request—including ultra-compact reducers with center distances as small as 6mm, or low gear ratios down to 2:1, ensuring that your specific motion control needs are fully met.

What Makes EtG Drive Different?

EtG Drive features a double enveloping worm design with an hourglass-shaped worm and a worm wheel machined with contoured tooth geometry.

This configuration achieves maximum surface contact between the components, delivering:

- High torque output in a compact size

- Greater load capacity and lower contact stress

- High resistance to shock loads

- Minimized backlash and smoother rotation

These advantages make EtG Drive ideal for robots, semiconductor equipment, packaging systems, CNC machines, and other environments where high precision and heavy loads are critical.

The compact, efficient design also provides clear benefits for space-constrained smart factory applications.

Trusted Technology, Flexible Production

EtG Drive is manufactured to AGMA standards, supported by EasternGear’s expertise in precision gear cutting, heat treatment, and tooth profile correction.

The company delivers fast lead times and full customization, enabling seamless integration into a wide range of industrial systems.

EasternGear is recognized as a leading domestic provider of double enveloping worm gear technology, combining technical reliability with the flexibility of custom production and application-specific design.

Looking for compact, high-torque motion control for your servo system?

Discover the EtG Drive series at www.epglab.com and request a customized solution today.

Address : 1376-1, Naksan-ri, Waegwan-eup, Chilgok-gun, Gyeongsangbuk-do, South Korea.

Media Contact

Organization: EasternGear

Contact Person: Lynn Kim

Website: https://www.epglab.com/

Email: Send Email

Country:Korea South

Release id:28296

The post Compact High-Torque Rotary Tables for Welding Automation From EasternGear appeared first on King Newswire. This content is provided by a third-party source.. King Newswire makes no warranties or representations in connection with it. King Newswire is a press release distribution agency and does not endorse or verify the claims made in this release. If you have any complaints or copyright concerns related to this article, please contact the company listed in the ‘Media Contact’ section

Related News

Circa Watch Labs Revolutionizes Luxury Timepiece Customization With Its Advanced Seiko Mod Builder for Ladies’ Watches

Spread the love United States, 8th Dec 2025 — Circa Watch Labs, a rising innovator inRead More

NET Accelerates Global Expansion, Tapping Overseas Markets with Solid Tonic Water Pocket Tonic

Spread the love South Korea, 8th Dec 2025 – NET, a food-tech company specializing inRead More